Suspension maintenance is key

You know how people sometimes say, “If it ain’t broke, don’t fix it?” This statement is probably the worst thing to ever live by when it comes to automobiles.

If you want to ensure that your vehicle remains in topnotch conditions for as long as possible, then maintenance is key.

From replacing the tires to checking the engine and even recharging the coolant for the AC, everything should be sound before you can confidently go out on the open road. Today, we’re focusing on the suspension parts.

Suspension system - what is it and what does it do?

In the simplest of terms, the suspension system consists of the parts of a vehicle which supports it as it moves on the road. If all roads were smooth, straight, and devoid of imperfections, then this system might not even be necessary.

Realistically though, from bumps and potholes to sharp bends and more, roads are anything but perfect. A standard suspension system works to maximize the friction between the tires and the road, thereby enabling the driver to steer and handle the vehicle with relative ease and comfort.

To put this further into perspective, imagine a moving car has a combination of two forces – ride and handling. Ride is the car’s ability to smooth out a bumpy road, whereas handling is its ability to accelerate, brake, and turn corners safely.

These are all a direct result of a functional suspension system. Your vehicle wouldn’t be the same without it, and probably wouldn’t survive a drive without these parts.

Note that a functional suspension system still requires an equally functional frame, steering system, and tires and wheels to provide the perfect automobile experience.

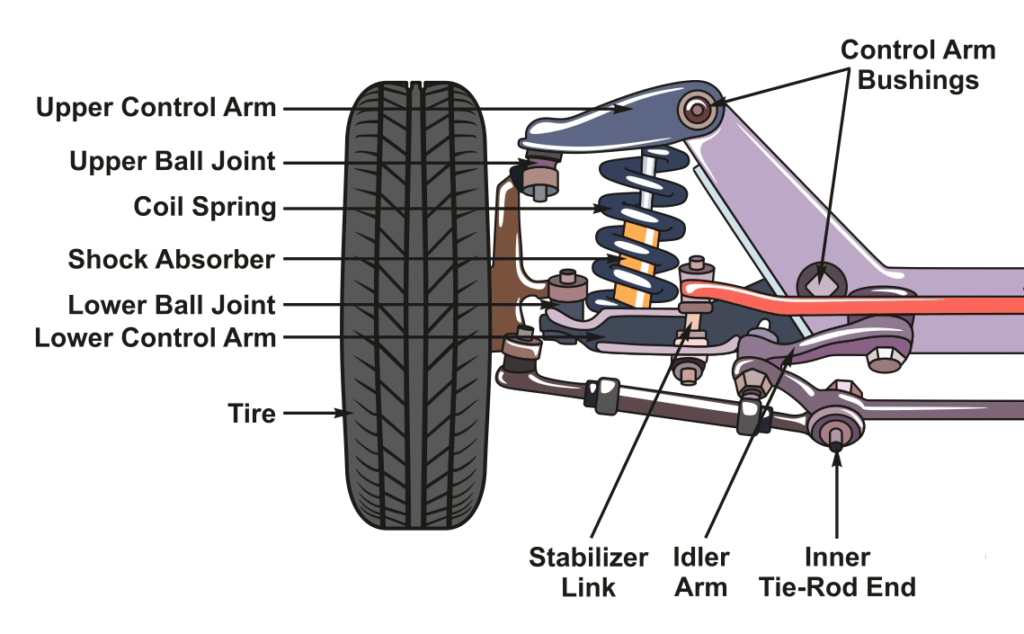

A review of the suspension parts

- Shock absorber

Also called dampers, these parts minimize spring bounce to ensure the wheels are always in contact with the road. This reduces the impact of bumps for a much smoother ride.

When these become damaged or weak, the vehicle tends to bounce somewhat erratically. There can also be tire cupping and shock absorber oil leaks as the shock absorber becomes worn out.

- Shocks and Struts

These reduce vehicle bounce, keep the wheels on the road, and ensure a smooth ride, all while supporting the vehicle’s weight.

When there is excess ball joint play and vehicle bounce, oil leaking from the shock body, missing bushings, or cupped tire wear, make sure to check this system. Chances are there’s something wrong with them or they’ve just gotten worn out.

- Coil springs

These not only absorb impact from irregularities on the road but also support vehicle weight to maintain optimum ride height. Without the function of springs, a vehicle would have excessive tire wear on one side, lower ride height, and also provide for an unstable ride.

- Bushings

Vibrations, strange noises, wobbling, and steering difficulties are issues you would have to deal with if your bushings get worn out. Functional bushings are meant to encase the ends of the control arms and provide a cushioning effect for the vehicle.

- Ball joint

These are a sort of a pivot point that allows the wheels to turn alongside the suspension. Without them, you will be subjected to a rather rough ride with some real steering difficulties.

- Strut mount/bearings

While the mount helps improve strut operation, the bearing enables it to turn with the wheels. When either of these features gets weak, expect difficulties with returning the steering wheel to the center, as well as some weird suspension noises.

- Control arms

These enable you to maintain appropriate wheel alignment. They attach the wheel hubs to the vehicle frame. A common sign of wear from them is the misalignment of the suspension.

Signs your suspension needs replacement

For some reason, this part of auto maintenance is not given the attention it deserves. Perhaps because issues with it are not as visible as a flat tire or smoke from under the hood.

However, a bad suspension doesn’t just affect the smoothness of your ride but also plays a huge role part in your ability to control your vehicle. At this point, you don’t need to be told that it’s pertinent to take it more seriously for your own sake.

How can you tell when your suspension parts have gone beyond minor maintenance efforts, but require a full replacement?

Call TLC For Immediate Assistance Regarding Your Suspension Needs

Here’s a few signs that should let you know when to take the car to the repair shop

- Rough ride

Just as mentioned in the reviews of each suspension part, most worn out parts significantly affect the smoothness of a car’s ride. When you begin to feel every bump on the road, then it’s probably time to check or replace some suspension elements.

- Uneven tire treads

You’re probably wondering what tire treads have got to do with the suspension system. However, it makes sense that an uneven car (due to suspension issues), would put pressure on different parts of a tire, therefore resulting in those uneven tire treads.

- Stopping with “nose dives”

Noticing a dip in the front end or a “nosedive” when stopping a car, or being lurched forward in your vehicle as you try to stop is a clear sign that your car shocks are worn out. This results in the jerking movement and its inability to minimize bounce.

- Issues with the steering

Almost all the suspension parts we discussed above had some part to play in turning the steering, keeping it in the right position, or just returning the wheels and steering column to center.

Poor steering response or even a stiffer steering wheel is an indication of worn-out suspension parts letting you know it’s time to get them checked out. That way, you can determine whether it’s an issue of the realignment of the wheel or full-on replacement of the suspension system.

- Mileage

Sometimes it’s best to stick with the consensus. Several automobile experts and manufacturers have determined most cars require suspension replacement after 50,000 miles.

Consider being a bit proactive here and not wait until it breaks before changing. Perhaps, when it reaches that 50,000 milestone or a little over it, you could replace it, or at least get it thoroughly checked out.

How often should your suspension system be inspected?

Like we mentioned above, most experts recommend replacing suspension parts after 50,000 to 100,000 miles. However, this is simply a recommendation that is based on general conditions.

Every driver has something unique about their car, driving style, and even the roads they drive on often. All these factors will affect the suspension parts differently. The bumpier the roads and more “James Bond” your driving style is, chances are your suspension parts are will wear faster than others.

Irrespective of how long you’ve been driving for, there’s only so much you can tell about the state of your suspension from a “wobbly” car. It’s best to have a professional inspect the car and let you know whether or not to replace the suspension system.

Good luck!

17 Responses

I really appreciate that you shared this amazing post with us, thanks for sharing and keep up the amazing work.

Thank you so much, Olivia!

King Country Trailer and Repair is a company run by truckers for truckers and therefore we will provide unparalleled levels of customer service and experience.

KCTR has over 30 years’ experience in the trucking industry which has helped us develop a true understanding of what business owners, managers, dispatchers and drivers are looking for in a dealership/service center. Whether you need a call out on a Saturday night or need a courtesy trailer to finish your delivery, KCTR has the resources and desire to be a true partner for you and your trucking company.

Thanks for your comment.

Thanks for writing this great article for us. I have gained good stuff from this website. Looking forward to your next article. I am happy to share this post to my friends. Keep it up.

Thanks, Olivia, we appreciate it.

Thanks for explaining that it would be smart to consider when you need to replace your suspension. It is great to know that it would be smart to do it sometime after 50,000 miles. That is good for me to know because I am planning on getting a car this upcoming year.

Thanks for taking the time to leave a comment. It´s great to hear the post has helped you.

I have been having trouble with my car wanting to veer to the left lately whenever I drive. Thanks for explaining that poor steering can be a sign that you need to take your car in to check its suspension. I’ll have to find a shop I can take it into soon before it gets worse so that I can be safer out on the road.

It’s good to know that suspension issues can lead to uneven tires. My brother was trying to fight out why his tire treads are uneven. I’ll let him know he may need to get new suspension parts soon.

Thanks for this interesting blog! We have been looking for this information and here we are really like to thank for your article and really it is much helpful and appreciate your work.

It’s good to know the role shocks and struts play in a suspension system. My husband’s car needs service on the suspension. Thanks for teaching me what parts may need to be replaced.

Come on time, be very polite to people reading its blog. All my questions were answered. I will definitely ask in the future how to succeed so well.

I love what you said about taking care of your car since it’s the second largest investment you’ll make. I’ll share this information with him so that he can look into his options for professionals who can help him with an oil change. Thanks for sharing!

I recently had a conversation with my brother on suspension repairs last Monday night when we met for dinner. He showed me how his suspension was worn out and he wanted help to look into it as well. Fortunately for him, I found your interesting post here which I might add is very informative. My favorite part has to be where you pointed out that poor steering response or even a stiffer steering wheel is an indication of worn-out suspension parts letting you know it’s time to get them checked out. You make a very good point here, one I’m sure those interested in getting these repairs done will be glad to be mindful of. Thanks for this! I’ll share this with my brother later today!

Hello there! Thank you for highlighting that knowing the operating pressure we would like to use will help drive the selection of the cylinder bore size. My friend wants to buy some spare parts for her food production equipment. I’ll ask her to remember this tip when she hires someone to repair it later.

THank you for your comment, Amy. We appreciate you.