What Is A Dielectric Test On A Bucket Truck?

Dielectric testing is an inspection process that is crucial for bucket trucks, manlifts, tow trucks, boom trucks, utility trucks, and other commercial vehicles. In short, the inspection ensures that the insulation on all of the electronic components on your vehicle are secure and working properly. This helps to ensure the safety of your workers, on and off the rig—as well as the optimal performance of your equipment.

All use of bucket trucks and other commercial vehicles are regulated by OSHA (the Occupational Safety and Health Administration) and ANSI (the American National Standards Institute), organizations that help enforce procedures and testing to keep workers and pedestrians safe in work zones and around commercial machinery.

DIELECTRIC

TESTING SERVICES

LONG ISLAND NY

Family Owned & Operated. 30 Years of Experience. Contact Us Now!

DIELECTRIC

TESTING SERVICES

LONG ISLAND NY

Family Owned & Operated. 30 Years of Experience. Contact Us Now!

In order to meet the legal requirements of using boom trucks and other vehicles, fleet owners need to maintain certain standards. This includes three mandatory tests—aerial lift testing, DOT testings, and dielectric testing—performed on an annual basis. If you need dielectric testing services for bucket trucks, please get in touch with us (631) 753-2211

- Why Is Dielectric Testing So Important?

- How To Pass Dielectric Testing For A Bucket Truck

- What Does The Dielectric Test For Bucket Trucks Include?

- How Much Does Dielectric Testing For Bucket Trucks Cost?

- What Are The Dielectric Testing Requirements For Bucket Trucks?

- Dielectric Test Equipment Identifies Insulation Failures

- Troubleshooting Procedures

- Next Steps

- Frequently Asked Questions

Why Is Dielectric Testing So Important?

If your business uses one or more man lifts, tow trucks, or other commercial vehicles, dielectric testing (which, in the case of bucket trucks, is often called hi-pot, or high-potential testing) is not only recommended—it is required. Failure to comply with these regulations (or the failure to repair issues identified in a dielectric test) is in direct violation and could result in legal or disciplinary action.

In addition to ensuring regulatory compliance, proper testing (as well as the recording of the results) can help detect existing issues with your vehicles. This allows you to make corrections or adjustments that will prevent future problems, hazards, and safety concerns—as well as reduce the potential cost you will have from correcting said issues.

The barriers of electric insulation on your vehicle protect operators and surrounding pedestrians from dangerous electrical currents moving through your equipment. Through appropriate testing, you can ensure that the peak level of voltage does not exceed the resistance of the barrier material—keeping your equipment from being damaged and preventing human injury.

Dielectric tests can also evaluate the integrity of your equipment on multiple levels, depending on the type of test performed. For example, a dielectric strength test is designed to evaluate how high the voltage needs to be before the insulating material allows it to flow through. Alternatively, a dielectric withstand test measures the amount of time the insulation can hold a high voltage current before it begins to break down.

DIELECTRIC

TESTING SERVICES

LONG ISLAND NY

Family Owned & Operated. 30 Years of Experience. Contact Us Now!

DIELECTRIC

TESTING SERVICES

LONG ISLAND NY

Family Owned & Operated. 30 Years of Experience. Contact Us Now!

How To Pass Dielectric Testing For A Bucket Truck

Safety testing is a requirement for boom trucks, bucket trucks, utility trucks, tow trucks, manlifts, and more. However, the individual requirements may vary depending on the type of vehicle, since each vehicle may have different electronic components. For bucket trucks in particular, especially insulated bucket trucks (trucks that are equipped with an insulated boom and bucket to protect against electric shock), required safety tests will include a thorough evaluation of the following aspects of your vehicle:

- Acoustic Integrity

For this test, the computer will analyze the sounds your vehicle makes while it is operating. The technology calculates the stability of your equipment by comparing the size of the truck and the loads it carries. Then, it determines a quality score. This grade is evaluated on a scale to determine whether or not your vehicle meets the necessary criteria in order to safely operate.

- Dielectric Integrity

According to the ANSI, a dielectric test verifies the electrical insulating strength in the FRP (Fibreglass-Reinforced Plastic) parts of upper and lower booms, buckets, liners, digger derrick extensions, tool circuits, and upper control systems on certain types of commercial vehicles. During the inspection, if any defects are found, the issues are classified according to severity.

- Structural Integrity

In this inspection, different parts of the truck are evaluated for functionality and condition. Though the specific parts may vary depending on the type of truck, the parts inspected usually include a minimum of twelve points of inspection:

- Outriggers

- Chassis

- Elbow structure

- Machine platform

- Self-recovery device

- Digger (when applicable)

- Upper boom

- Material handler

- Lower boom

- Pedestals

In order to ensure that your vehicle passes inspection, it is crucial that you keep all of these parts in good working order with regular maintenance, repairs, and internal inspections. Other suggestions for proper maintenance of your vehicle can be found in manufacturer’s guidelines, owners manuals, and in the guidelines for your affiliated regulatory agencies.

Additional tips to pass a dielectric inspection

- Keep a calendar of required testing deadlines, repairs, and other maintenance requirements—and sync the dates with your devices.

Keep your vehicle clean using the appropriate soaps and waxes.

Maintain a policy to inspect every vehicle before and after each trip.

Encourage operators to promptly report issues, repairs, and concerns with management, so that they can be verified and addressed.

Keep a quick reference guide with all OSHA, ANSI, and any other applicable regulations for each vehicle.

- Keep your paperwork, records, repair receipts, and certifications organized and available.

What Does The Dielectric Test For Bucket Trucks Include?

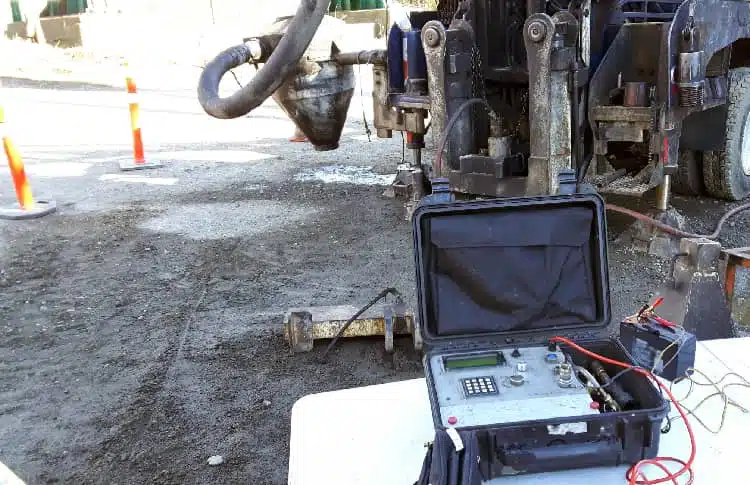

During a dielectric test, a trained and certified technician will run a current of alternating current (AC) or direct current (DC) electricity into different areas of the machine, at multiple points or locations. They will then measure the leakage or voltage given off by the equipment. The results of the test will help the technician evaluate if the electronic insulation has an appropriate amount of resistance to harmful voltage levels.

- Oil Spectro-Analysis

Evaluates potential pollution, contamination, and effectiveness of oil fluids.

- Stability Test

Evaluates the physical integrity of various points.

- Thickness Test

Evaluates the thickness of various mechanical parts according to the standards.

These tests are especially relevant to DOT (Department of Transportation) requirements, rather than OSHA or ANSI. The results of these tests will determine whether your vehicle gets certified as having passed the test, or whether further repairs, updates, and inspections are needed before you may continue using the vehicle.

Dielectric Test Verification

- The peak voltage does not exceed the capacity of the insulation.

- The user will be adequately protected from electrical hazards.

- There are no signs of insulation damage, aging, defects, or other issues.

- The device complies with any related OSHA or ANSI standards.

How Much Does Dielectric Testing For Bucket Trucks Cost?

Dielectric testing can cost anywhere from a few dollars to a few hundred dollars. The cost of dielectric testing varies based on the type of equipment, the specific areas being tested, and more. It may also vary depending on where you get your testing done. That is why we recommend contacting your technician for a more accurate quote.

dielectric testing requirements for bucket trucks

OSHA, ANSI Inspections, and DOT all require insulated bucket trucks and man lifts to get tested at least once per year. They may need to test more often if a problem occurs, since they will need to verify that the problem was resolved.

According to all three of these organizations (in particular, the ANSI 92.9 Dielectric Testing regulations), dielectric testing requirements include, but are not limited to optimal dielectric integrity of the following:

- Outriggers (Ex. pads, bolts, hoses, etc.)

- Chassis (Ex. truck frame, suspension, brakes, etc.)

- Pedestal (Ex. mounting bolts, welds, diagonal brace, etc.)

- Rotation Bearings (Ex. bearing movement, torque, and attachment)

- Turntable (Ex. structure, bucket-leveling cables, leveling cylinders, etc.)

- Lower Boom (Ex. structure, welds, hydraulic system, etc.)

- Elbow (Ex. structure, hydraulic hoses, and leveling cables)

- Upper Boom (Ex. wear pads, hydraulic lines, jib structure, etc.)

- Platform (Ex. mounting bracket bolts, leveling system, control operation, etc.)

- Digger/Auger (Ex. mounting arm, housing, gearbox, etc.)

- Winch (Ex. mounting brackets, gearbox, controls, etc.)

- General (includes load rating chart, electrical hazard placards, and more)

In addition to general evaluation and dielectric testing services, your provider will also perform the following tests to determine the condition of the aforementioned sections of your vehicle:

- Acoustic Emission (AE) Test

A test to determine the acoustic integrity of the vehicle, as detailed in the previous sections.

- Magnetic Particle Inspection

Used to identify cracks on ferrous material, such as welds, plates and castings.

- Dye Penetrant Inspection

Used to identify cracks on ferrous material, such as welds, plates and castings.

- Ultrasonic Inspection

Used to detect flaws in accessible critical pins. This reduces the number of pins that actually need to be removed for inspection.

- Torque Test

This involves torque testing (ensuring flushness or tightness) of all accessible areas including bearings, gearboxes, and mountings.

Dielectric Test Equipment Identifies Insulation Failures

In addition to determining the general safety of your equipment, dielectric testing has the ability to detect various faults and failures, which might not be obvious otherwise.

Failure Detection Checklist

- Chemical contamination of your insulation.

- Physical damage or deterioration of the insulating material.

- Moisture absorption, which can affect the way it conducts electricity.

- Issues with how the insulation material surrounds the equipment, which can be caused by partial discharge ionization.

- The use of improper insulating material, inadequate for withstanding electric current.

Factors that affect dielectric testing results for bucket trucks

While there are a variety of factors that could cause your bucket truck to fail its dielectric test, the following are the most common problems:

- Damaged Surfaces – Most booms on bucket trucks have an insulating, waterproofed gel coating designed to protect the fiberglass underneath. If this gel gets damaged, this can allow moisture to leech into the fiberglass insulation and affect the electric regulation.

- Improper Cleaning – Failing to regularly clean your vehicle can result in the accumulation of debris accumulating on or inside the boom, which can also conduct electricity. In addition, using inappropriate soaps or waxes can increase the boom’s ability to carry currents.

- Lax Maintenance – Maintaining the appropriate tightness of all rotation bolts, especially those used for mounting between the truck and boom, is an essential aspect of passing dielectric tests.

- Environmental Damage – Trucks that are left out in adverse weather conditions, harsh sunlight, and other rough environmental situations can cause damage to the surfaces, insulation, or electrical components of the vehicle.

If you do fail a dielectric test, be sure to look into these issues as potential causes. You can also see the next section for other troubleshooting suggestions.

DIELECTRIC

TESTING SERVICES

LONG ISLAND NY

Family Owned & Operated. 30 Years of Experience. Contact Us Now!

DIELECTRIC

TESTING SERVICES

LONG ISLAND NY

Family Owned & Operated. 30 Years of Experience. Contact Us Now!

Troubleshooting Procedures

If your boom truck fails the test once, the technician will likely perform one or more troubleshooting procedures.

- Clean and dry the area being tested.

- Remove the part in question to examine it more closely.

- Remove or replace potentially problematic parts.

- Gently abraid scuffs and scratches, then clean and dry the area.

- Inspect the interior of the boom for carbon tracking, dirt, or damage.

- Perform a DC test on the protective gel coat surface.

At this point, the technician may have identified the problem by finding a damaged part, debris, or other contamination. If possible they may try cleaning, waxing, or replacing the part to see if that solves the problem. Once these procedures have been performed, the technician will run the test again.

If it passes, they know that they have rectified the problem. If the test fails a second time, they will work to identify the problem and make recommendations for corrective measures. Usually, if a part fails the test after being cleaned (and obvious damage being ruled out), it is likely that the part is compromised internally and would need to be replaced altogether.

Next Steps

Once the testing is complete, the technician will give you a detailed report of the results, including a quality score that ultimately declares whether or not your vehicle passed the test. They will also give you a list of defects (if any were found) and indicate the levels of severity of each problem, so you know how to prioritize your bucket truck repairs.

If any of these repairs are required to be completed before you vehicle can be certified, the technician will also provide you with a list of any additional inspections needed after the repairs and updates are complete.

Frequently Asked Questions

Does OSHA require annual dielectric testing of bucket trucks?

Yes, OSHA requires yearly bucket truck dielectric testing. States may also have their own regulations for the inspection and operation of your vehicle. You can find an example of this in the California Code of Regulations, as set forth by their Department of Industrial Relations.

Who can carry out dielectric testing for bucket trucks?

Dielectric testing for bucket trucks must be performed by trained personnel and/or certified dealers. These technicians must also use certain approved equipment and testing methods. You can find more information on these regulations on the ANSI and OSHA websites.

How long does the inspection take?

Dielectric inspections usually take less than 10 minutes. The test itself takes between 1 and 60 seconds. The technician will also need several minutes to analyze the results. The overall service time will also depend on the service provider you are using and their current work queue.

What happens after an dielectric test?

After a dielectric test, the technician will give you your results in the form of a quality score, which indicates whether or not your vehicle passed. If present, they will also include a list of issues that need to be resolved, categorized by severity. If your vehicle fails the test, the technician may perform one or more troubleshooting procedures and try the test one more time.

Summary

Dielectric Testing Does Not Have To Be A Struggle

A dielectric withstand or hi-pot test is an important aspect of maintaining compliance performance of your aerial lift truck. It ensures that your vehicle has the capacity to perform properly while regulating the flow of electricity in a way that does not damage your equipment or harm operators. To keep your fleet compliant and safe—and reduce potential costs—be sure to maintain a regular schedule of inspections, maintenance, and repairs to keep your bucket trucks in good working order.

You should also do what you can to keep your vehicles clean, undamaged, and away from harsh elements. If you do fail a dielectric test, know that the technician is there to help; they will make suggestions for improving the condition of the failed vehicle so it can be reevaluated and back on the road in no time.

More Resources

DIELECTRIC

TESTING SERVICES

LONG ISLAND NY

Family Owned & Operated. 30 Years of Experience. Contact Us Now!